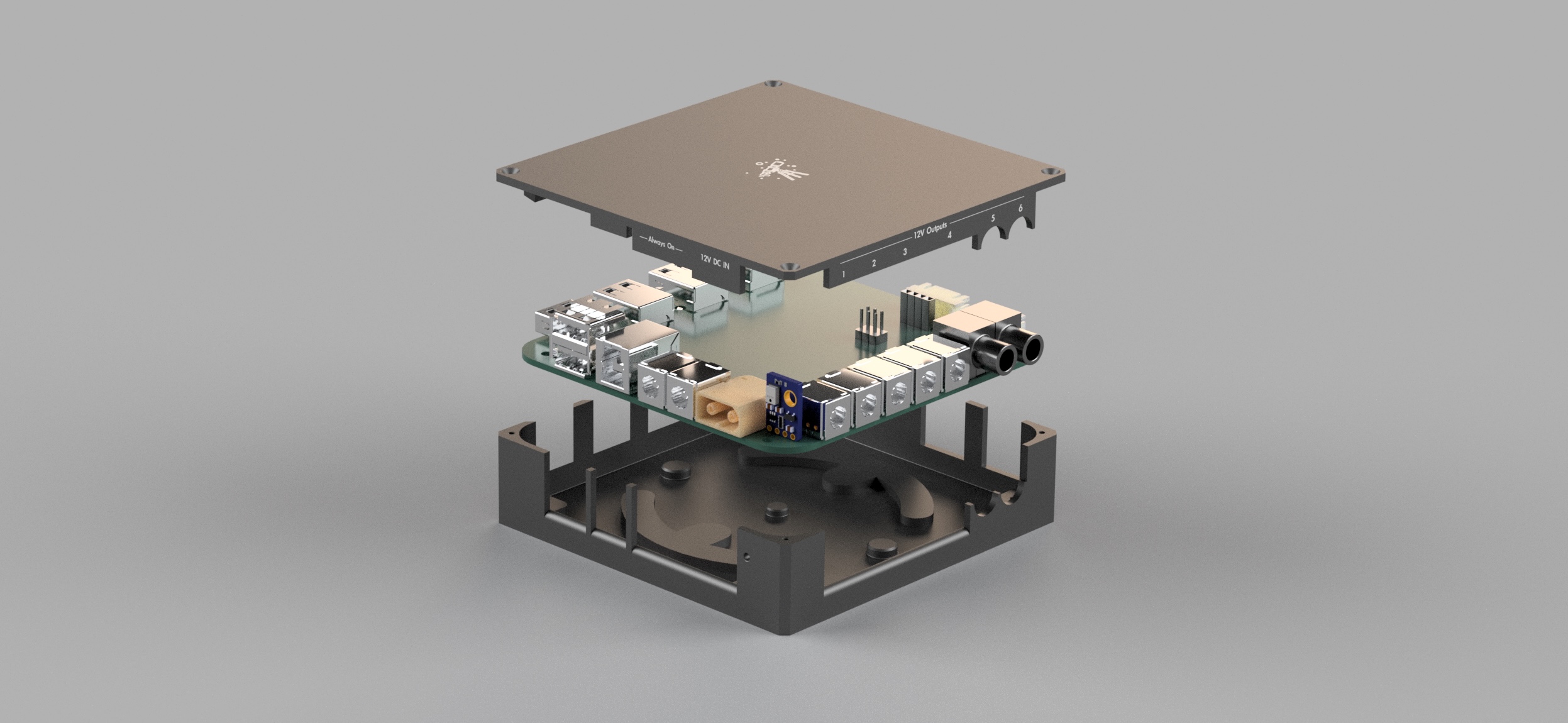

The enclosure transforms this from a DIY project into something that actually looks like a real product. Your choice of material impacts durability, heat dissipation, ease of use, and aesthetics.

CNC Machining (Premium Choice)

Pros:

- High-grade aluminum = rugged, weatherproof, and built to last.

- Excellent heat dissipation.

- Allow threaded inserts for easy mounting.

- Supports laser markings for professional-looking labels.

- Available in different colors for a sleek finish.

Con:

- Expensive (but worth it if you want a pro-level build).

3D Printing (Budget Choice)

Pros:

- Much cheaper than CNC.

- Easy to reprint if damaged.

- Tough materials like PETG and ASA can handle the job.

Cons:

- Requires a 3D printer that can handle PETG/ASA.

- Not as durable — prone to warping in heat.

- Threads wear out fast (metal inserts help but require thicker design).

- No laser markings — stickers or prints won’t look as clean.

What I Did?

Easy: Printed first to test, then ordered CNC! - Best of both worlds.

Files & Ordering

Find all 3D (.STEP) files in my GitHub repository.

- Each version includes:

- Box folder → 3D file + PDF with thread specs (for CNC).

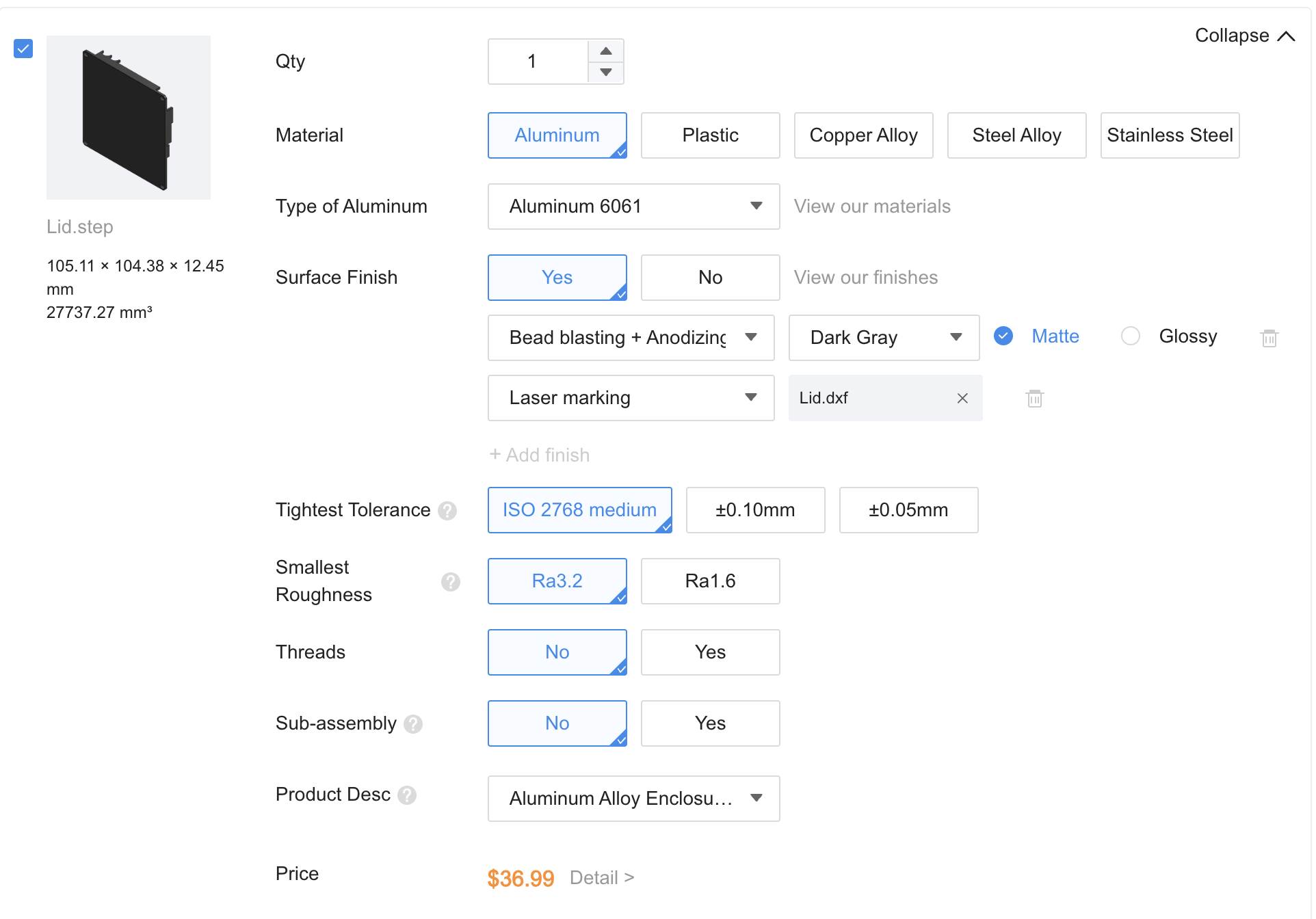

- Lid folder → 3D file + DXF file for laser marking.

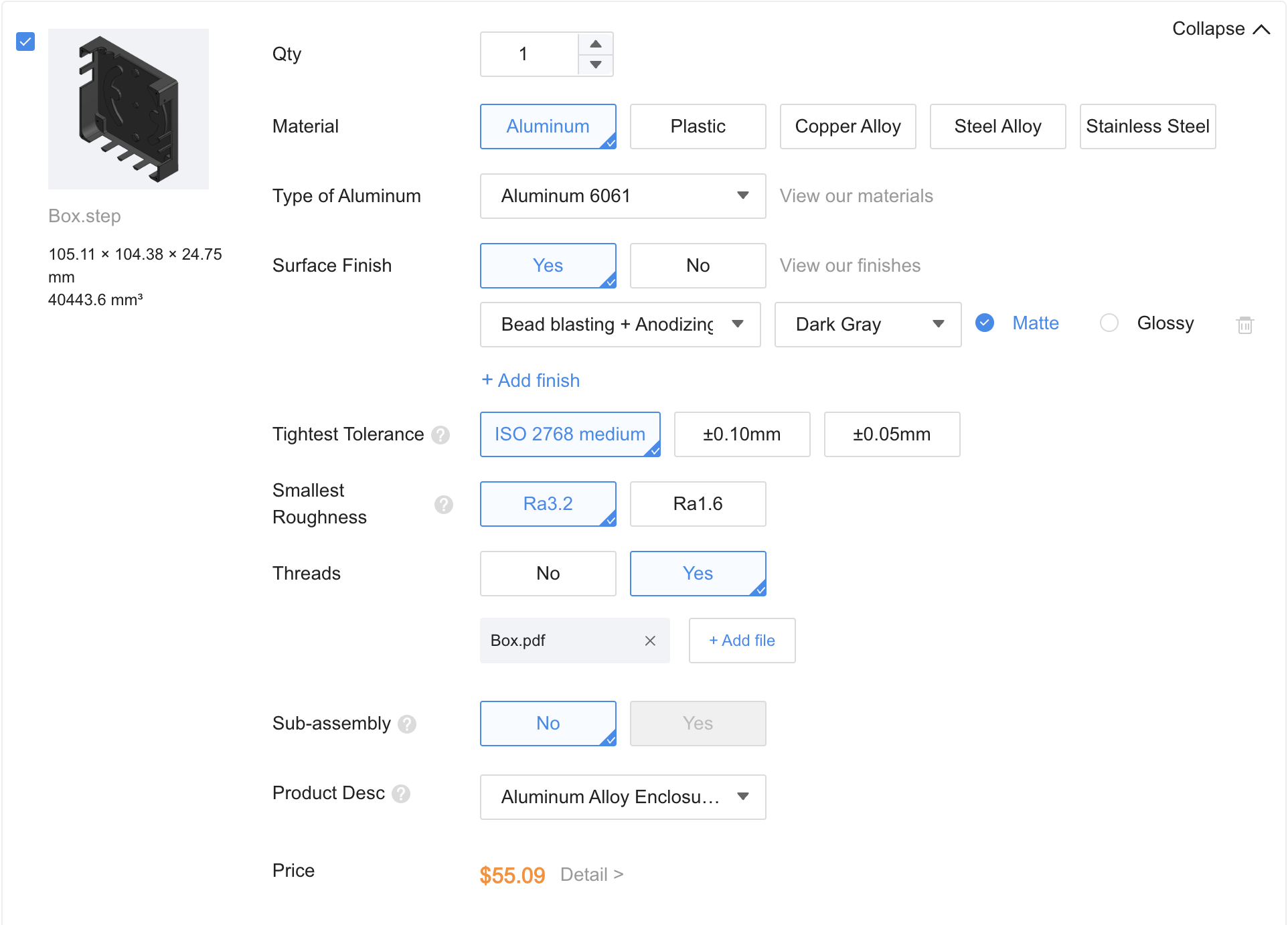

Ordering CNC (Recommended)

- I used JLCPCB’s CNC service, but you can choose any manufacturer.

- Settings to choose:

- Material: Aluminum 6061

- Surface finish & color

- Threads: Upload the PDF file

- Laser markings: Upload the DXF file

- Choose the cheapest shipping option before submitting your order. This will request a quote (usually ready in 24 hours).

Get Ready for the Next Step!

Next up: Drivers & Software. Let’s bring this beast to life!

Want the PCB, microcontroller, components, CNC or 3D prints and pre-installed firmware delivered to you?

Send me an email or use the contact form

Want to buy me beer 🍻? Use this link

See you soon!

~The Bright Knight